Fully automatic mother-and-child car curing kiln production line

——Full-process automation solution, leading the new benchmark of building materials manufacturing

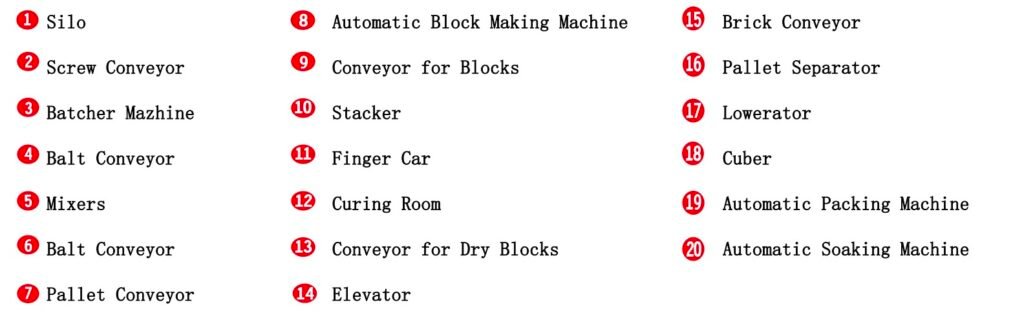

I. Overview of the whole line

Yonggong Machinery’s intelligent brick-making whole-line production system integrates six core modules: brick-making host, RGV mother-and-child vehicle, curing kiln, fully automatic brick stacking machine, fully automatic baling machine, and soaking machine, realizing full-process automation from raw material processing, molding, curing to stacking and packaging. The average daily production capacity of this production line can reach 100,000 standard bricks, and the labor cost is reduced by 70%. The modified production line is suitable for medium and large brick factories, municipal engineering and solid waste resource projects, helping enterprises to build automated modern factories.

II. Core equipment and synergistic advantages

1. Intelligent brick-making host (QT10-15 model)

· Efficient molding: Adopting servo hydraulic system, molding pressure 20MPa, suitable for raw materials such as concrete, fly ash, and construction solid waste.

· Intelligent interconnection: Built-in Internet of Things module, real-time upload of production data to the central control system, support remote fault diagnosis and process optimization.

2. RGV mother-child vehicle conveying system

·Precise logistics: The child vehicle is responsible for taking the wet bricks from the brick making machine and transferring them to the mother vehicle. The mother vehicle delivers the bricks to the curing kiln along the track, with a positioning accuracy of ±1mm and a conveying speed of 30m/min.

·Flexible scheduling: Through the intelligent allocation of tasks by the system, it supports parallel operation of multiple caves.

3. Intelligent curing kiln

·Controllable temperature and humidity: Layered and zoned temperature control (30-80℃), steam curing cycle is shortened to 6-8 hours, and energy consumption is reduced by 40%.

·Automatic in and out of the kiln: Linked RGV system to achieve unmanned loading and unloading.

4. Fully automatic brick stacking machine

·High-speed stacking: The modified equipment is used for stacking cement bricks in the block production line, which can realize the reserved holes in any layer of stacking, reduce the floor space of finished bricks, and effectively improve work efficiency.

5. Fully automatic baler

·Intelligent bundling: Adopting arrow-through packaging technology, combined with PET strapping tape, a series of tightening, welding and other actions are completed to complete a packaging process. The entire operation process is highly automated and can be flexibly adjusted according to different cargo sizes and packaging requirements without excessive manual intervention, effectively reducing manpower input and operational errors.

· Unmanned operation: Automatically identify the stack type and adjust the bundling path, supporting cross bundling, tic-tac-toe bundling and other methods.

6. Soaking machinery

· The soaking machine mainly processes the brick blanks by completely immersing the formed brick blanks in a specific soaking liquid.

· Energy saving and environmental protection: The recycling filtration system reuses water, reducing water waste and emissions. The equipment has low energy consumption during operation. The use of energy-saving motors and optimized transmission systems further reduces production costs, which is in line with the development trend of energy saving and environmental protection.

Whatsapp Official Account

- Address: No. 152 North Street, Xiadu Community, Liucheng Street, Nan'an City, Quanzhou City, Fujian Province, China

- Tel: +86 13655952326

- Email:lily@qzmachinery.com

Please fill in your info and we will contact you soon.

Please fill in your info and we will contact you soon.