QT18-15/QT15-15

Fully automatic cutting and forming machine

Product Overview

QT18-15/QT15-15 brick making machine is a high-performance fully automatic hydraulic brick making equipment designed for brick factories, integrating efficient production, stable operation and convenient operation. The equipment adopts an upgraded hydraulic system and intelligent control technology, which can quickly produce various concrete blocks, pavement bricks, PC imitation stone bricks and other concrete products to meet the large-scale production needs of brick factories. With its strong durability and low failure rate, QT18-15 has become an ideal choice for many customers to increase production capacity and reduce costs. The equipment supports a variety of raw materials such as clay, fly ash, construction waste, industrial solid waste, etc., and is suitable for different production scenarios.

2. Product Features

·Equipped with an independently developed control system, seamlessly connected with the hydraulic system and mechanical parts, realizing electromechanical and hydraulic integrated control, so that the whole machine can run efficiently to achieve the best working conditions.

·Powerful self-diagnosis and guidance functions, real-time monitoring and display of system operation status, timely shutdown and alarm prompts when faults are found. And provide solutions and processing methods, just like a famous teacher on the scene.

· Imported PLC programmable controller, color touch screen, more user-friendly operation interface, parameter guidance and other practical functions are selected to allow users to easily realize human-computer dialogue.

· Adopt German high-performance hydraulic technology and dual hydraulic drive system. The vibration is stronger, the molding cycle is shorter, and the product strength is higher.

· Adopt the original high-performance vibrating system of West Germany, with strong vibration, short molding cycle and high product density.

· Adopt suspended two-way positioning material car with small running resistance to solve the impact of the thickness error of the pallet on the product.

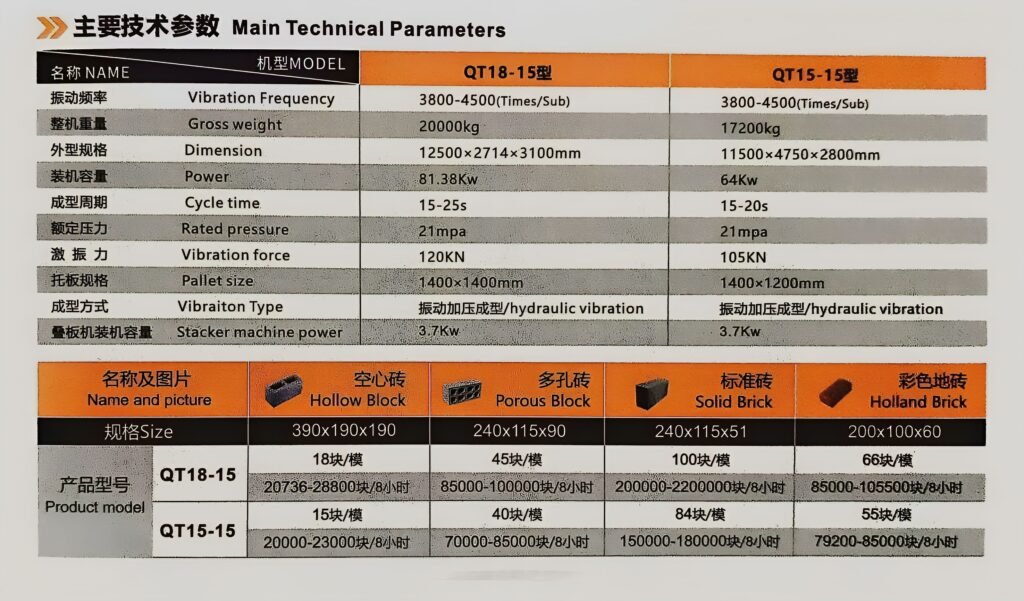

3. Main technical parameters (picture as follows)

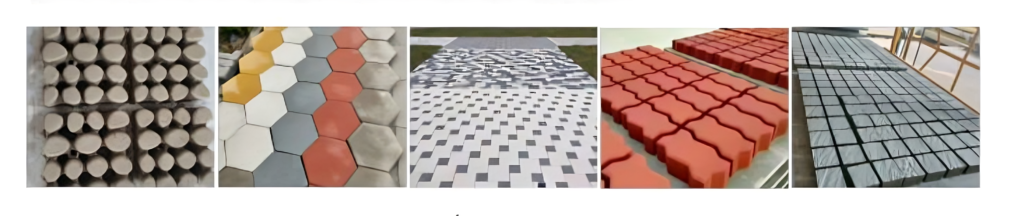

4. Product details (picture as follows)

5. Case site (picture as follows)

6. Applicable fields

· Building blocks: hollow bricks, porous bricks, standard bricks, etc.

· Municipal building materials: permeable bricks, colored floor tiles, slope protection bricks, water conservancy engineering bricks, etc.

· Environmental protection projects: using fly ash, construction waste and other solid waste resources to produce green building materials (support solid waste utilization and reduce raw material costs).

Whatsapp Official Account

- Address: No. 152 North Street, Xiadu Community, Liucheng Street, Nan'an City, Quanzhou City, Fujian Province, China

- Tel: +86 13655952326

- Email:lily@qzmachinery.com

Please fill in your info and we will contact you soon.

Please fill in your info and we will contact you soon.